May 30, 2020

Fighting food waste: the benefits of digitalisation

Introduction

What actually is Food waste? Four terms can be isolated to establish a framework regarding food waste1:

- food availability (production of the whole food supply-chain);

- oversupply (difference between quantity produced and quantity actually consumed);

- waste (amount of oversupply that fails to be recovered for nutrition);

- degree of fungibility (ease with which oversupply can be recovered).

In the category of waste it is included food that gets spilled or spoilt before it reaches its final product or retail stage, and food that is fit for human consumption, but is not consumed because it is either left to spoil or discarded by retailers or consumers.

In the following sections some data about food waste will be illustrated; then, the necessity for digital solutions to reduce food waste will be highlighted; in conclusion, we will talk about Wenda, an Italian startup backed by European investors offering an Information Management Hub for advanced supply chain tracking used by main Food&Beverage players, improving quality, logistics and sales.

Food waste numbers

According to FAO data2, Each year, roughly one third of world food production destined to human consumption is lost or wasted across the food supply-chain, to the value of 750 bn $. It is a huge amount, that corresponds to approximately 1,3 bn of tons in food. 58% of the food produced is wasted before even arriving to the consumer, and almost 20% of food global loss is due to cold chain disruptions.

In the EU, each year roughly 88 million tons of food are wasted, costing around 143 mld € and, if nothing will be done, Food waste could reach 120 million tons by 2020. Furthermore, 20% of global Food waste is caused by cold-chain issues (i.e. the truck engine stops, logistics do not respect contracts, the driver stops under the sun etc, and FIT with a software and hardware system helps to discover and manage this issues …).

In Italy the trend does not seem to be different: Food waste in Italy is worth more than 3,5 bn € each year, from the fields (946.229.325 €) to industrial production (1.111.916.133 €) to wastage in distribution (1.444.189.543 €), a figure that, added to household food waste, brings us to more than 15,5 bn € thrown away each year (0,94% of GDP)3.

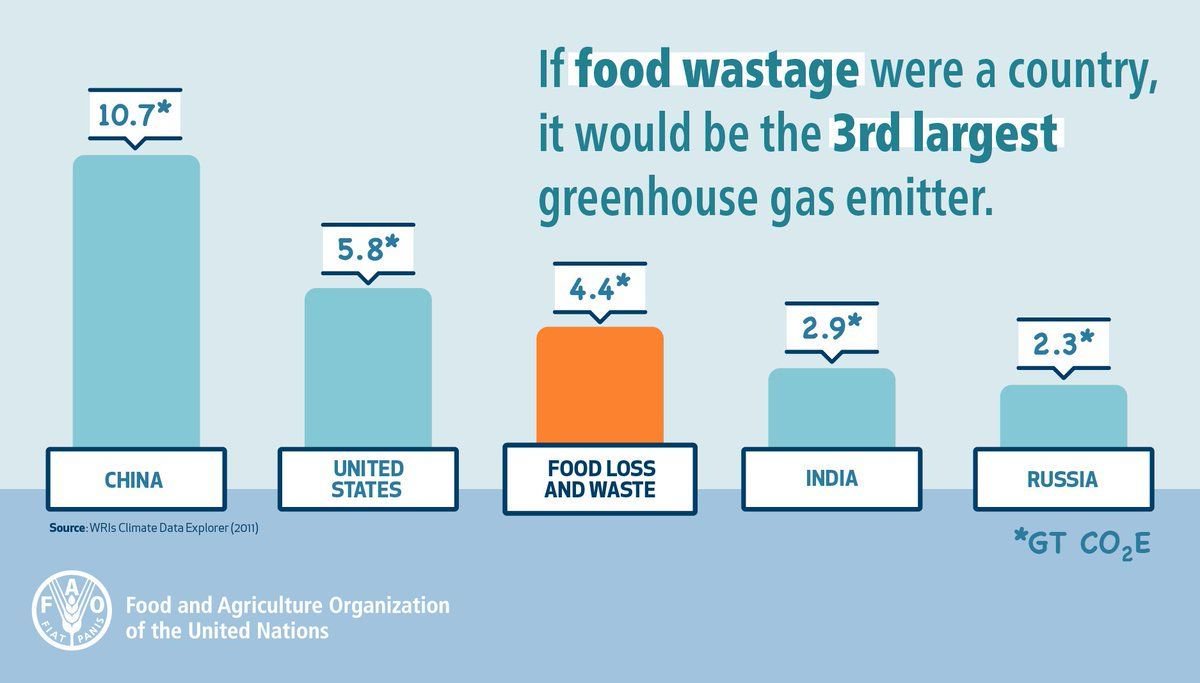

Food waste produces a large consumption of resources such as water, land, energy, labour and capital, and unnecessarily generates GHG emissions, contributing to global warming and climate change. In middle- and high-income Countries, Food is mainly wasted in the last stages of the supply chain, while consumers’ behaviour is crucial.

The abovementioned FAO study identifies the lack of coordination between actors in the supply chain as a contributing factor: farmer-buyer agreements can be helpful to increase the level of coordination. Additionally, awareness campaigns among industries, retailers and consumers, the implementation of virtuous reuse processes and the dissemination of digital solutions are among the recommended measures to reduce Food waste. Here we will focus on supply chain enhancement through digital services and solutions.

The benefits of digitalisation

One of the key elements to reduce Food waste is the enhancement of supply chain efficiency: digital solutions for the supply chain management enable a better demand/offer coordination, make transactions more efficient, empower product traceability and give the possibility to shape a dynamic pricing based on the product’s residual shelf life.

For instance, according to BCG4 the widespread adoption of digital solutions could imply annual savings for 120 mld US$. Beyond these considerations, given that a substantial part of wastage is caused by poor product-preservation conditions, limited food traceability, damages suffered during transportation or failure to meet best practices at the stage of logistical handling, companies tend to adopt digital solutions to provide convincing answers to these issues.

According to a study5, to this day the digital revolution intervenes in a major way to ensure food traceability, reducing wastage, boosting revenues and increasing process efficiency: 36% of agrifood companies, thanks to the implementation of digital solutions, has experienced reductions of time and costs connected to the processes of data collection, management and transmission.

In this scenario, we are seeing a steady growth of cold chains global value, which no later than 2022 will reach a total value of 271,3 bn $, with a 7% CAGR , while up to 2020 250 bn $ will be spent in IoT solutions for food traceability – 40 of which in the single segment of traceability systems for logistics – with a 30% CAGR.

Another element to be considered is the generally insufficient access to traceability, quality and general product-related data, not very well shared along the chain, rarely reaching the consumer. Big players are going in this direction: for instance Maersk6, the world’s largest container shipping company – which, by the way, selected Wenda7 as one of the 10 best startups in the world fighting for food waste.

WENDA: Information Management Hub for Food&Beverage supply chains

Wenda, an Italian startup backed by European investors, managed to note in advance the necessity for the use of digital services and solutions to reduce Food waste, e has created an Information Management Hub for advanced supply chain tracking used by the main Food&Beverage actors , improving quality, logistics and sales. It consists of a web platform that can support all Food&Beverage actors operating with perishable or sensitive products: data loggers are inserted into each box, pallet or container of any given shipment, in order to collect environmental data (geolocalisation, temperature, Food integrity); data are sent to the Wenda Information Management Hub, the web platform that aggregates, compares and processes them.

Subsequently, you can follow in real time and from a single control point the product’s conditions via advanced integrity analytics embedded in the Hub, gaining knowledge of the hazard points in the distribution chain, ensuring the best product care and enhancing internal processes. In this way, you can have end-to-end supply chain visibility to ensure transparency, maximise products’ shelf life and increase efficiency.

In this way, you can gain end-to-end supply chain visibility to ensure transparency, maximise products’ shelf life and increase efficiency in potential recall campaigns: producers, distributors and retailers will be able to substantially reduce both losses and Food waste, which today appears unacceptable.

As claimed by former FAO director general, José Graziano da Silva: “All of us—farmers and fishers; food processors and supermarkets; local and national governments; individual consumers—must make changes at every link of the human food chain to prevent food wastage from happening in the first place, and reuse or recycle it when we can’t. We simply cannot allow one-third of all the food we produce to go to waste or be lost because of inappropriate practices, when 870 million people go hungry every day”.

To have further information, to know more about us or to schedule a demo of the Wenda Information Management Hub, we invite you to visit our website: https://www.wenda-it.com/.