Collaborative supply chain & logistics

- Supply chain collaboration and collaborative logistics

- What has changed?

- What is a Multi-enterprise supply chain business network?

- How to recognize a collaborative logistics solution?

- Which technologies do enable collaborative logistics solutions?

- Why do organizations need a collaborative solution?

- What are the real benefits?

- How to make collaborative solutions work in SMEs?

- Conclusions

- Notes

Indice contenuti

We usually tend to reduce the results of globalization to the news we read or the things we buy but it brought much more than this. First, it had an enormous impact on the supply chain and logistics. Today, it is impossible to think about a supply chain or logistics operation managed only by a single party or a single country. The inevitable result of this is the growing need for collaboration between the parties.

Everybody talks about collaboration but do we actually know what it means for a supply chain operation or why is it important and, moreover, what impact it can have on organizations?

Supply chain collaboration and collaborative logistics

Collaboration in supply chain and logistics means building supply chain operations on a culture of visibility and collaboration across all the partners.

In today’s supply chains disruptions are inevitable. Professionals involved in the process need to deal with unanticipated changes on a daily or weekly basis. However, since they need to navigate around different siloed and functional supply chain applications, they are not always able to mitigate the risks associated with these disruptions. Major losses can be avoided if we build working connections.

"The connection is a core element in all supply chains."

If you think about it internally, you will see that processes, plans, people, and data created out of them are all connected inside an enterprise. If you think about it externally, on the other hand, you will see that enterprises are connected one to another. Since one enterprise alone cannot assume all roles, it will partner with other organizations, and entrust them with some crucial part of their operations. These connections with external partners will create the external supply chain of an enterprise, i.e. your external network.

Efficiency and cost savings become real, when key supply chain data, processes, plans, and people are connected both inside and outside of an enterprise. This way only, a supply chain can be streamlined.

There is no doubt that, compared to the past, today's supply chains are more complex and difficult to manage.

Think about it: a company buys products from a wholesale supplier, works with a logistics company to transport them, and then sells them in a third-party retail store. Each of those suppliers has suppliers of its own and its own logistics partners. There are different responsibilities for each segment and product chain of custody changes. Moreover, these operations can include multiple tiers of suppliers and/or multiple geographies. The actions and adjustments made by individual suppliers, distributors, production facilities, and channel partners affect one or more of the others.

"It means supply chains are extended."

There is only one way of surviving in this extended ecosystem: collaboration, data, and management. In order to enable these last two, we turn our faces to technology.

What has changed?

Traditional systems are inward-looking. Today, companies buy TMS, WMS, etc., and connect everything to an ERP, pretending it can do everything. With the external supply chains generating the majority of information, unfortunately, ERP systems and other business applications that companies have used for decades, are not able to solve the level of complexity that we are experiencing.

These systems were designed to solve the problems of the enterprise, not the problem of the supply chain ecosystem. As a result, many companies are relying on exchanging Excel files with partners in order to fill this gap. However, these methods come with some limitations:

Manual data-entry

Risk of human error

A limited number of partners and information

Not automated, slow and sequential

Limited support for traceability

Siloed information

Therefore, using a system designed and developed with a single enterprise focus cannot be the answer to managing multi-enterprise focus and extended supply chains.

"Simply, it is like choosing the wrong size of shoes: you will not be walking barefoot but you will slow down and struggle since it is not the right fit."

Here, the problem is not purely technological but more conceptual. In order to make the extended supply chains work, we need to shift our focus from single enterprises to multi-enterprises and create a functioning network. It means to stop thinking that our enterprise can stand in the market alone, without considering external factors that can impact only the long term: external relations can have high short term impacts.

What is a Multi-enterprise supply chain business network?

The term, “Multi-enterprise supply chain business networks (MSCBN)” coined by Gartner, defines this as “a community of trading partners — of any tier and type within a network — that needs to coordinate and execute supply chain processes across multiple enterprises.”¹

A supply chain network that connects all parties and allows them to operate as one virtual supply chain, to work off the same set of information, always up-to-date. Some also use the term “network of networks”. Since being connected does not mean only one singular network but different networks should rather be connected to each other. A good real-life example is how the telecommunications providers interoperate naturally with their peers, to ensure you can call a friend who’s using a different provider than yourself.

The definitions and bold terms might seem complicated but the concept is simple:

"One’s supply chain data feeds the other’s supply chain process."

For example, the shipment information provided by a supplier will trigger the action of the carrier that will pick up the goods. The pick-up information of the carrier will be shared with the wholesaler (customer in this case). The wholesaler will organize its warehouse activities (inbound and outbound) according to the information received.

A survey conducted by Gartner shows that by 2023 more than 50% of organizations operating in the supply chain market space plan to share data across the partner ecosystem, establish common processes to operate it and have a technology platform in place to integrate with ecosystem partners.²

A collaborative and multi-enterprise supply chain software supports the different lines of business (procurement, supply chain, demand planning, order management, etc.) with solutions to make better and faster decisions using the up-to-date information from all the supply chain partners involved – from the end customer all the way to the raw material or parts supplier.

A collaborative supply chain software then should guarantee:

Single platform

Shared, single version of the truth

True end-to-end visibility and collaboration among supply chain partners

Automation, always up-to-date information

Complete support for traceability

As a result, collaborative software extends what ERP has done for the company within its organization and it provides a secure network for companies to coordinate supply chain activities in real-time. A pair of shoes that fits perfectly, speeds you up and eases your daily problems.

How to recognize a collaborative logistics solution?

Once the conceptual problem is solved, we can move forward with the technological one. So, which technologies can enable collaboration and management in supply chain and logistics?

"Numerous players offer network solutions with multi-enterprise support, however, not all of them are supply chain networks."

Some of them offer only certain features of the solutions. For example, many technology companies are building networks of partners across specific niches in the supply chain like networks for transportation partners, air and ocean, freight forwarding, manufacturers and distribution.

The ideal multi-enterprise solution should include at least the following capabilities:

Multi-Party Network Collaboration: providing an integration layer to connect internal and external systems and parties and existing specialized networks to help you form a connected and collaborative network. A shared platform is essential.

Real-time Visibility: providing real-time, end-to-end supply chain visibility into all events and milestones for the order across all internal and external parties.

Events Management: enabling the planning team to re-plan and quickly manage exceptions in order to ensure OTIF.

Order and Inventory Management: order and inventory management functionalities with intelligent automation in orchestrating micro supply chains for each customer with optimized order flow across time, capacity, costs and inventory.

Analytics Dashboards: including predictive and prescriptive analytics, analysis of root causes and impacts.

Certainly, there are other features and functions that can be offered but these are considered the basis for a collaborative solution. The key value in these solutions is enabling real-time and intelligent process execution by providing normalized data, pre-built connections to major partners and other services. The solution and the applications should create shared value for both the primary tenant and its network partners.

Which technologies do enable collaborative logistics solutions?

In the evolving technology landscape, 3 technologies, in particular, are taking an important role in these solutions:

Cloud: cloud-based shared and interoperable platforms providing common and shared methods and the ability to achieve process synthesis.

Big Data Analysis: analysis of big and unstructured data sources allowing greater visibility for optimization.

AI and Machine Learning: leading more autonomous operations over time.

Lastly, the architectural platform supporting all this must be modern, which can operate processes across all the partners in the network.

"Digital supply chain ecosystems will become more and more important."

According to a Gartner survey, more than half of organizations operating in the supply chain area plan to share data across the partner ecosystem, establish common processes to operate it and have a technology platform in place to integrate with ecosystem partners.³

Why do organizations need a collaborative solution?

As mentioned above, in today’s highly connected supply chains, companies face numerous challenges in managing them efficiently.

According to Gartner, these challenges include:

The activities and data mostly reside outside the enterprise.

Business applications to run them are not connected.

Leveraging available data is very difficult.

Engaging and collaborating with all business partners is time-consuming.

Leveraging many internal enterprise data and having enterprise-centric processes can not be a solution to overcome these challenges. This is because this approach leads only to delayed updates, limited visibility insights, a reactive mode for both planning and execution, optimization by object rather than outcome, and decision making mainly based on humans. From a technology perspective, on the other hand, it leads to relying on legacy solutions and often on-premises solutions.

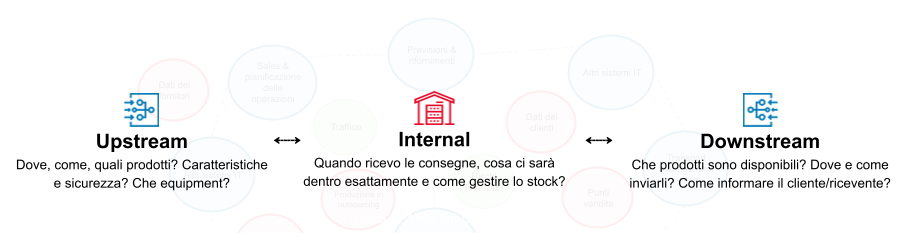

Besides having applications in place to manage core enterprise capabilities (such as ERP, CRM, etc.), companies should look for solutions and business applications to connect with their business partners end to end, upstream and downstream. This will increase visibility and improve the insights leveraged.

The collaborative solutions including different organizations are designed to create this kind of connection between the parties and enable collaboration among them.

What are the real benefits?

Minimize risk

Today’s supply chains frequently encounter blind spots, such as failing to anticipate trade disruptions and supplier risk. The results can be extremely challenging for companies.

According to a survey conducted by Gartner, as of 2021, 68% of supply chain executives report that they have been constantly responding to high-impact disruptions over the last three years. And 67% report they have not had sufficient time to recover from a disruption before another high-impact event has disrupted their supply chains again. Moreover, a recent McKinsey & Company’s recent research found that over a 10-year period, firms may lose 42% of their annual profits due to disruptions. These blind spots can be avoided by increasing the visibility over internal but, most importantly, external processes.

A collaborative, multi-enterprise solution, alongside providing real-time, end-to-end supply chain visibility into all events and milestones for the order, connects all parties on a shared platform and allows them to share a single version of the up-to-date information. These will simplify the risk identification process, making organizations take action much sooner. Consequently, even if it will not be possible to mitigate every single risk that the company encounters, the quantity will definitely be minimized.

Increase Efficiency

Efficiency is all about the extent to which a process uses resources in the best way possible to ensure the fast, smooth running of systems.

"There is no “single, one-time cure” to achieve the most efficient supply chain."

It’s a process that needs to be reviewed and optimized as often as possible with a continuous improvement methodology in mind. In order to do it right, you need accurate data and analysis of your operations, which will help you to identify areas of improvement where further efficiency can be achieved.

Therefore, it is logical to think that the more you store data on your supply chain, the more accurate solutions to increase efficiency will come out. A collaborative, multi-enterprise solution will provide you with not only your supply chain data but also the data of your external partners. Moreover, it will provide you with a common environment to work together, eliminating time-consuming manual activities like phone calls or report preparations.

Reduce Cost

A poorly designed supply chain network can lead to inadequate use of your resources. In these networks, any poorly-managed touchpoint between you, your suppliers and/or customers will raise costs, increase risks and result in poor customer service.

So, a well-designed multi-enterprise network, facilitated by accurate data over your internal and external operations, will lead you to the optimum use of human, technological, financial or physical resources and reduce operational costs and time wastage.

How to make collaborative solutions work in SMEs?

According to supply chain professionals, small and medium enterprises (SMEs) often are driven by the practical needs that the market generates. These organizations experience high levels of sales pressure deriving from the desire for growth.

"This leads them to adopt a reactive supply chain management approach."

While the corporates and big enterprises adopt strategic supply chains, considering it as a competitive advantage. The supply chain should be a strategic topic also for SMEs.

Having a reactive supply chain management approach naturally leads to thinking about everything short-term and segmented or in silos, which is not something that helps to navigate the current market scenario. Supply chain disruptions, poor customer experience and external intangible risks touch a medium-sized company more than a larger one.

The insights gained from real players in the market showed that in order to make a multi-enterprise and collaborative solution work in an SME environment, the solution providers should focus on some important aspects.

SMEs should try to see the big picture

The issue is not about not being aware of the problem or not thinking about collaboration with external parties. It is about the fact that the SMEs identify the most evident pain points in their supply chains and look for short-term and practical solutions to eliminate them, often not taking into consideration the root causes. This can easily lead to opting for different systems for each pain point and managing their processes in silos.

Being able to see the big picture, understanding the root causes, and analyzing the processes and operations as a whole could help identify the most suitable solutions from the beginning. It also enables them to minimize the company risk and provides the basis for sustainable long-term growth.

Multi-enterprise collaborative solutions are not corporate-exclusive

These solutions are often not known by small and medium enterprises (SMEs). It is hard to look for a solution that you are not familiar with. It is critical to make these organizations understand the value hidden behind this complicated term. A collaborative multi-enterprise solution can offer a mix of light and simple supply chain software functions, allowing operational management as well as data analysis. The difference is about offering those as “multi-enterprise enabled”. It will help you to boost your internal operations and your extended supply chain!

Last but not least, hence the need for collaboration is known and accepted by most of the organizations in the global supply chain landscape, independently of their size, the collaborative multi-enterprise solutions should not be corporate-exclusive, meaning accessible only by big enterprises with significant economic resources.

Extended supply chain solutions do not compete with ERP or TMS/WMS..xMS

Daily talking with CEOs, supply chain professionals, operations managers, logistics specialists and quality officers shows that a supply chain system is often compared to a vertical management system (e.g. a TMS); it is not properly correct, as vertical management systems look inside the company processes and at very specific operations. Whereas a supply chain system has a broader scope, to report on multiple verticals, collecting data from TMS, WMS, etc, having strong data analytics capabilities and eventually planning. If the supply chain tool is built with many-to-many architecture, strong data capabilities, multiple-users accounts and help to work with external business partners, it can be considered a tool for your extended supply chain, a multi-enterprise and collaborative one.

Conclusions

Companies need to interact and work together to grow their businesses. A multi-enterprise network solution can enable collaboration among companies in supply chain and logistics and help them to simplify the risk identification and decision-making processes. Most importantly, it helps to create a common environment to work together, reducing the time-consuming manual activities to the minimum, if not eliminating them completely.

Notes

Magic Quadrant for Multienterprise Supply Chain Business Networks, Gartner 2020

Predicts 2022: Supply Chain Strategy

Ibidem

How do supply chains change after unforeseen events?

How do supply chains change after unforeseen events? Collaboration without digitalization: mission (im)possible?

Collaboration without digitalization: mission (im)possible? Communicate the customer's order status with a single cloud platform

Communicate the customer's order status with a single cloud platform