Visibility, traceability and transparency of the supply chain

- What does supply chain visibility actually mean?

- Why is supply chain visibility important?

- 2 pillars of supply chain visibility: traceability and transparency

- Why do traceability and transparency matter?

- How to achieve 100% working supply chain visibility

- The future of the supply chain visibility

- Conclusions

- Notes

Indice contenuti

In the global economy, disruptions in the supply chain become the order of the day. Think about delayed shipments or other errors in the logistics networks. Any operator in the supply chain area has had to manage a disruption caused by events like these two examples. It is an indisputable fact that this can obstruct manufacturing or delivery plans. The consequences can arrive down to the customer and across product lines causing not only an economic loss but also, in some cases irreparable, reputational damages. The problem is when there is limited visibility over these events, the resolution part can be slow and painful. Most companies are forced to react to disruptions without key information.

What does supply chain visibility actually mean?

Many supply chain operators know so little about their supply chains. Even the most mature organizations have true real-time visibility into only small portions of their supply chain. Moreover, 84% of chief supply chain managers indicate a lack of visibility across the supply chain as their biggest pain point. But what does supply chain visibility actually mean?

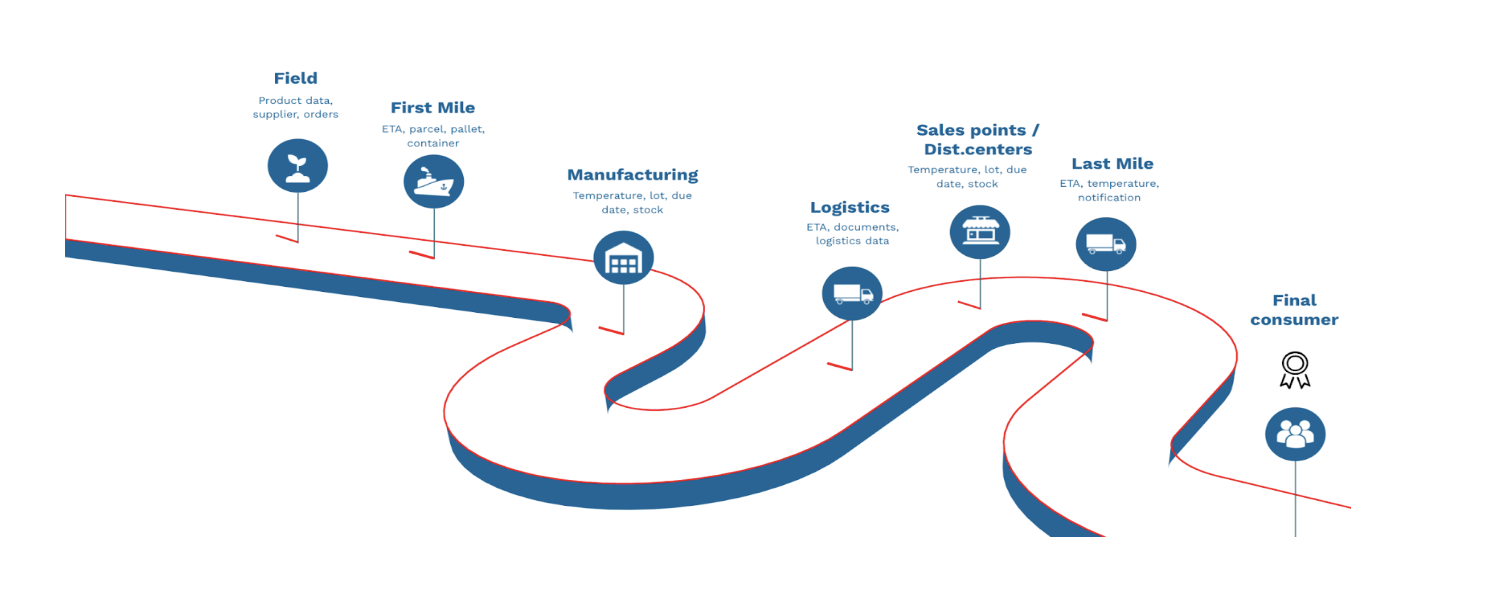

Surely, there are many well-structured definitions but, in order to materialize it, it is important to go beyond those definitions and truly understand their meaning. Supply chain visibility is about obtaining on-demand and real-time information on the status, condition and location of your products, materials and inventory anywhere around the world at any point in the supply chain journey.

The supply chain journey, of course, includes having visibility over different steps, like from supplier to manufacturer, from manufacturer to wholesaler and so on. So, it is not only about having insight into your internal data but having connected data from manufacturers to the final delivery of products readily accessible when needed. In other words, enabling an “end-to-end” supply chain visibility.

Why is supply chain visibility important?

Supply chain visibility became more important as companies outsourced parts of their supply chains and lost control and visibility over what used to be part of their own operations. The inclusion of various actors in the supply chain increases the variety and quantity of the information involved in the process and complicates the management.

“Visibility can provide the information links needed to understand ongoing supply chain processes and minimize the surprises.”

Take for example a retailer that is preparing for a new product launch and has so little visibility over the time of arrival of the product. This will have a direct impact, first, on the distribution of the products to the stores, which will create a domino effect on other activities. The warehouse receiving the goods from the supplier will not be able to plan the inbound and outbound activities; the stores will not be able to plan the inbound activities; the marketing team will not be able to plan the launch of ads and TV spots. Moreover, in the case of an unexpected event, all of these will be transformed into an increase in operational costs, poor customer service and even profit loss.

2 pillars of supply chain visibility: traceability and transparency

Supply chain visibility is constituted of two important pillars: traceability and transparency. These two terms are often used interchangeably.

Many people refer to traceability when they actually mean transparency and vice-versa. However, they are in fact two different concepts.

“Understanding the difference between the two concepts is fundamental for developing a functioning supply chain visibility mechanism and managing critical operations.”

Let’s take a closer look at these terms.

What is traceability?

Traceability is the process of tracing your processes, products and their inputs, from the very beginning of the supply chain through manufacturing to end-use. In simple terms, it is about capturing granular information about your products and processes. While traceability of products ensures the accuracy of the information including origin, composition, batch-lot data and condition data, traceability of processes guarantees accurate information on location, status milestones and other operational information.

The intent of traceability is to provide electronic information about the history of product movements, including all custody changes over time and be able to determine at a certain moment, who is the current owner of a given product. When traceability is guaranteed, you can identify the exact location and conditions of a specific product unit and the company (the business partner) in the possession of it.

What is transparency?

Transparency, on the other hand, can be simply seen as an activity of mapping the supply chain, collecting high-level information like a product’s components, names of suppliers, locations of facilities, associated certifications, etc. According to Business for Social Responsibility (BSR), transparency is defined by what data you are going to be transparent about, to whom, and how often, or when¹.

Who: Who needs to have visibility and access to supply chain information?

What: What information is being shared, and in what format, and for what purposes?

When: How often will the information be shared and updated?

Traceability vs Transparency

If we compare traceability and transparency, we can see that traceability is about generating data about the origin, location, and condition of products and transparency is about communicating this information. So, traceability focuses less on mapping the entire end-to-end supply chain but on following certain batches of components or purchase orders as they move through the supply chain.

“Finally, traceability relies on transparency: without transparency, more detailed information is virtually impossible to gather.”

Why do traceability and transparency matter?

Traceability and transparency work together to help companies gain better visibility of their global supply chains and ensure compliance with safety, sustainability, and social responsibility requirements. Your organization can have access to its operational data only after identifying who is in its supply chain and which of your supply chain partners collects this information. After the transparency is assured, the organization can focus on collecting granular data and enable traceability.

Transparency and traceability, together, allow companies to offer better customer service, identify pain points, respond to changes in demand, effectively manage recalls and certify sustainable processes and products. They support risk management, brand protection and customer engagement across supply chain networks.

Identifying potential supply chain risks and increasing operational efficiencies

Complete transparency and well-pursued identification of the companies and organizations within the supply chain at every tier help risk assessment and prioritization of suppliers and actions within a sustainable sourcing strategy. Simply, knowing who your business partners are and what role and impact they have on your supply chain helps you to reduce the risk of counterfeit products and mitigate risk from lower-quality components. The usage of higher quality products will result in a competitive advantage.

The traceability of the product, on the other hand, will minimize the risks related to product waste or product loss. Therefore, the detailed information on your products will increase operational efficiency thanks to the reduction in lost inventory, faster inventory turns and, for the temperature or humidity sensitive products, real-time condition tracking.

“You will be able to intervene just in time, if not before, in order to resolve disruptions or mitigate risks.”

It will also reduce the effort required to collect and process data and reporting (e.g. during audits). This will help you to allocate better resources internally and increase efficiency.

Meeting the requirements of customers and regulators

The granular data and complete information on the status, condition and location of your products not only help provide a better customer experience and consolidate the brand’s image but also guarantee product safety. It is not wrong to say that traceability and transparency may even help you increase sales by attracting new customers, who are looking for traceable, verifiable products.

Today, governments, consumers and other stakeholders put companies under pressure to divulge more information about their supply chains. For example, food companies receive this pressure on sharing more information about ingredients, animal welfare and food fraud.

“A study conducted by MIT Sloan School of Management shows that consumers may be willing to pay 2% to 10% more for products from companies that provide supply chain transparency.”

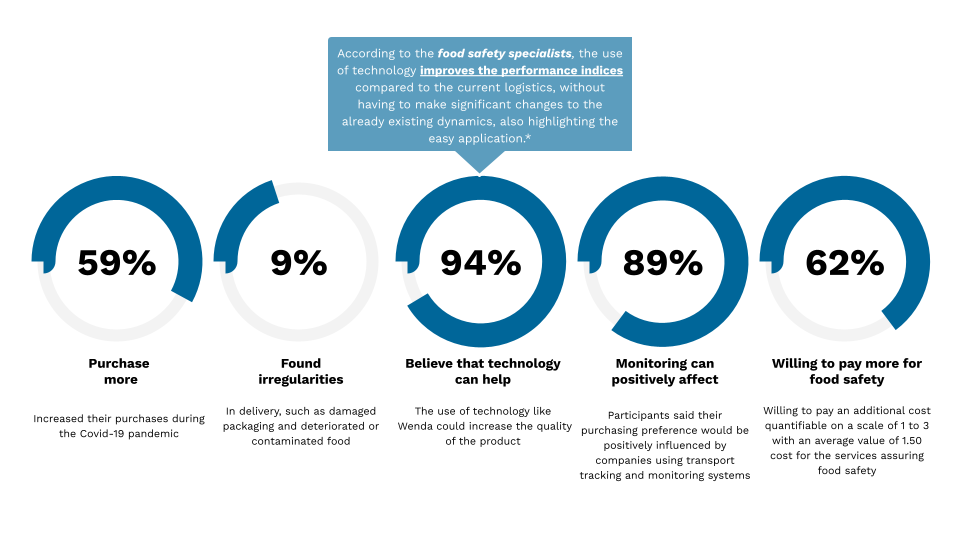

Another study, conducted by the University of Milan in cooperation with Wenda, showed a similar result: 89% of consumers stated that their purchasing preference would be positively influenced by companies using transport tracking and monitoring systems. 62% of consumers are willing to pay an additional cost quantifiable on a scale of 1 to 3 with an average value of 1.50€ cost for the services assuring food safety². This stresses both the importance of traceability and transparency.

Therefore, knowing what is happening upstream in the supply chain and being able to communicate this information to downstream stakeholders is the only way to ease the pressure and respond to these demands.

How to achieve 100% working supply chain visibility

Those who operate in the supply chain are well aware that having visibility throughout the entire supply chain is an urgent requirement but it is not always clear how to achieve it. The path that leads to supply chain visibility is intricated and surrounded by various challenges but it is not impossible. We brought together some fundamental steps that will guide you to establish a 100% working supply chain visibility.

“Your first aim should be to build the two load-bearing pillars of supply chain visibility: traceability and transparency.”

In other words, you need to gather granular information about your products and processes and identify what information to share, to whom, and when.

4 steps to achieve this goal and listed from more obvious to most complex one:

Digitalize your data

The first and fundamental step to take is digitizing all paper-based records and manual processes. Without a digital source, it is not possible to start your visibility journey and gather accurate insights into your operations. This will be the foundation of your traceability work providing you with electronic information about the history of products and processes. Digital record-keeping will not only allow you to store and process a large amount of data both from within your organization and externally but also will lead you to transparency by enabling various ways of information sharing.

If your organization has already passed this first waymark, maybe you can take this digitization to the next level by using technologies like Cloud, Big data, API and IoT. These technologies will improve your storage and processing capabilities; simplify the data sharing process and capture invisible information like condition data.

“Afterwards, having a clear data strategy is imperative.”

You need to manage and standardize the data you collect. Cleansing and defining consistent data models can help you to consistently utilize and translate the data into meaningful information.

Gather reliable data & Overcome silos

After you have built the foundation of your visibility, you should ensure that it is strong enough to carry your visibility weight.

“At this stage, your battle will be to gain transparency both internally and externally.”

Once you have a clear understanding of all the stakeholders in your supply chain, you will be able to know who is in possession of what information and you can, finally, enable a mechanism of information sharing.

However, obtaining the information is not always easy. If we think about freight visibility, for example, most organizations have limited access to data, they are only notified when their shipments reach checkpoints, such as a seaport, but they don’t know their products’ locations and conditions while they are in transit. If a certain part of a product gets damaged or lost in transit, it may be extremely difficult to know where and when the damage took place.

Another difficulty can be that your data is stuck in your ERP, TMS, or legacy software and these siloed systems do not share data with one another.

The only solution is to find the right connectivity platform. This platform should be technologically agnostic and neutral meaning being able to integrate, regardless of the technologies or execution systems in use. It should be able to connect all key players and ensure that all intended parties can easily access the data.

Leverage the data

You arrive at the third waymark of the path after you successfully build the two pillars of your supply chain visibility and you are confident that they will not collapse. Now, you can go into details.

Interpreting and leveraging the granular data that you collected will allow you to proactively manage exceptions before they occur, saving your business time and money while keeping a high level of customer satisfaction. Being able to identify the problems and critical points will give you the ability to discover opportunities to improve.

“A complete supply chain visibility is not only about seeing the big picture but seeing a high definition one, with all the details.”

Data analysis, Artificial Intelligence, and Machine Learning will be the enabling technologies for this step.

Build an extended supply chain network

When you digitized your data, gathered all the reliable data together and leveraged it in order to get trustful insights that led you to more data-driven decisions, it means you successfully arrived at the final waymark in your path.

Diminishing the supply chain visibility efforts is a common mistake made by many organizations at this stage.

“Arriving this far gives a false sense of security but we should remember that today’s new digital environment requires a collaborative approach to managing your supply chain.”

In order to get the best of all your business partners’ capabilities into a single environment, you should develop an extended supply chain network.

The future of the supply chain visibility

In the past, it was enough to capture product information at process milestones. However, in today’s supply chain this practice is far from satisfying the supply chain visibility requirements of organizations.

Today, consumers are expecting to have products delivered within the shortest time. There is great pressure on supply chains to meet these flexible expectations of the consumers. Supply chain managers must make sure the right products are in the right place at the right time, budgeted appropriately, and replenished as needed.

Having limited or static visibility over the supply chain cannot provide access to a real-time picture to manage every aspect of the chain, moreover, may result in risks and inefficiencies.

“For all these reasons, today, the supply chain visibility is shifting from “indication of a point in time” to “presentation of progression of things” through your supply chain.”

Real-time and constant supply chain visibility has the ability to provide alerts in the case of disruptive events. This enables your organization to take corrective actions immediately and solve key business problems.

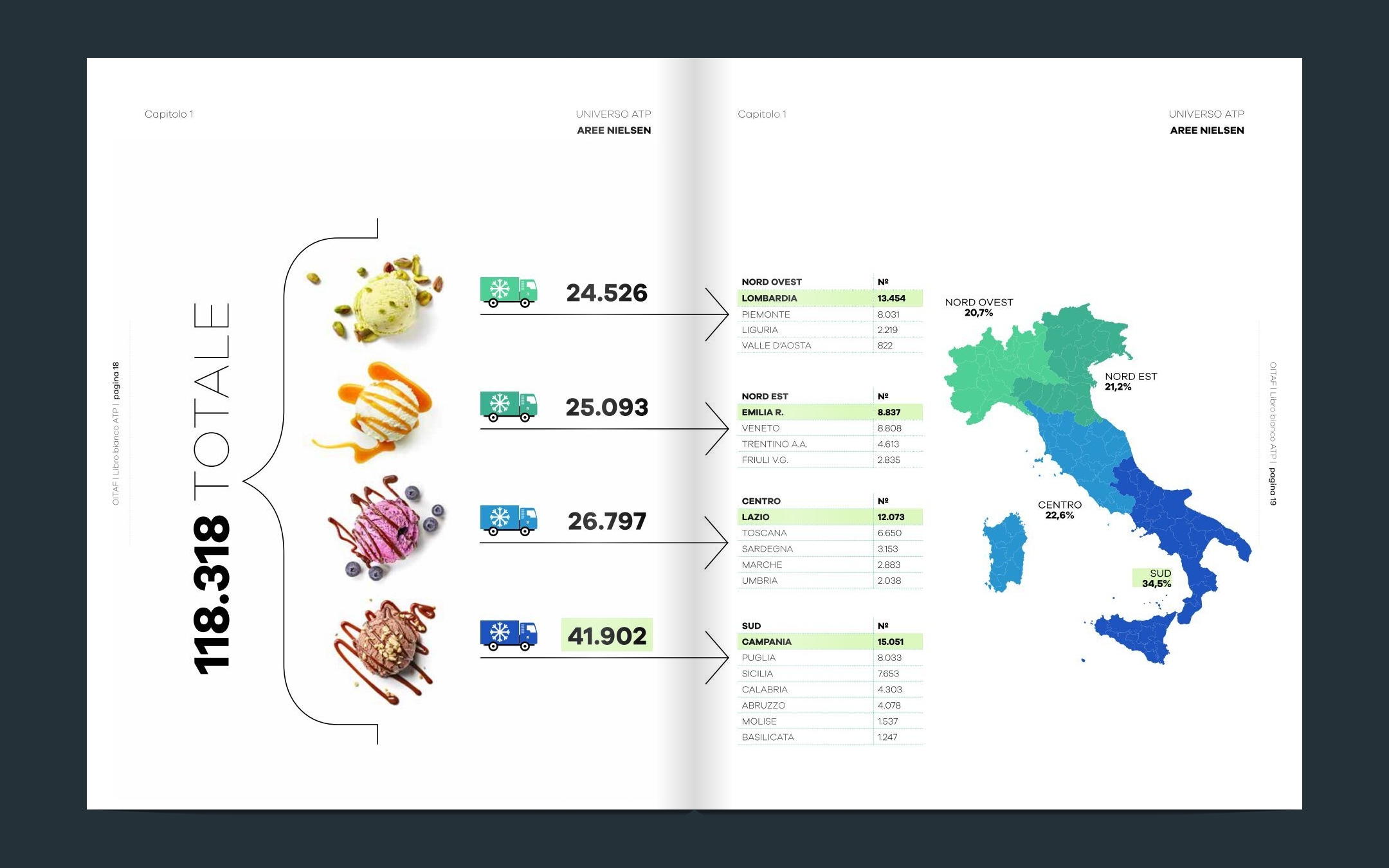

Think for example transportation of ice creams, a process that requires particular temperature control. A temperature increase at some point during the transportation can cause spoilage of the product. The driver may not even be aware of the situation and can arrive at the delivery point and come across this unpleasant situation. Being alert in case of these events and being able to communicate this information to your customers can prevent various business risks.

With a complete supply chain visibility solution where the traceability and transparency pillars are solid, this is possible.

Conclusions

A complete supply chain visibility is only possible through traceability and transparency. The future of supply chain visibility is about gathering granular information about both products and processes; sharing this information with the right stakeholders at the right moment; being able to give meaning to information collected; and, finally, it is about building an extended supply chain network.

Notes

Supply Chain Visibility: Traceability, Transparency, and Mapping Explained | Blog | BSR

These are the results of a questionnaire administered by the Dipartimento di Scienze Veterinarie per la Salute, la Produzione Animale e la Sicurezza Alimentare "Carlo Cantoni" (VESPA) of the University of Milan from May 12 to June 12, 2021, involving 303 people. The questionnaire was administered as a preliminary study for the Good Hygiene Practise (GHP) Manual written by the University of Milan in collaboration with Wenda for the Last Mile Safe Food Delivery project. For more information, please contact Wenda.

Food & Pharma Transport: the new ATP White Book

Food & Pharma Transport: the new ATP White Book Tracking at the parcel level: what do we do wrong?

Tracking at the parcel level: what do we do wrong? What are the solutions for tracking products at the item level?

What are the solutions for tracking products at the item level? Improving supply chain management with tracking data

Improving supply chain management with tracking data