More efficiency in the supply chain with data and process automation

- Invisible robots: Software automation in supply chain and logistics

- What is process automation?

- What are the main technologies enabling process and data automation?

- 1. Artificial Intelligence (AI)

- 1.1 Machine learning (ML)

- 1.2 Natural Language Processing (NLP)

- 2. Optical Character Recognition (OCR)

- Simplified explanation: how does process and data automation work?

- What are the use cases of process and data automation in supply chain and logistics?

- Why do companies automate their supply chain and logistics operations?

- Notes

Indice contenuti

Throughout history, automation has represented an opportunity to create new value from the balance of the classic paradigm of people, process and technology. Automations enabled with hardware quickly proved themselves since their accomplishments are visible and tangible for our eyes. The software automations are mostly overlooked and missed since they are not in our sight and work silently. Software automations, namely process and data automation, however, changed the way we do business today. It has even changed the way consumers or citizens interact with businesses or government organizations. It started with simple task automations in the 1960s with the introduction of Enterprise Resource Planning (ERP) systems and today evolved into automated workflows and operations that control themselves without any human intervention.

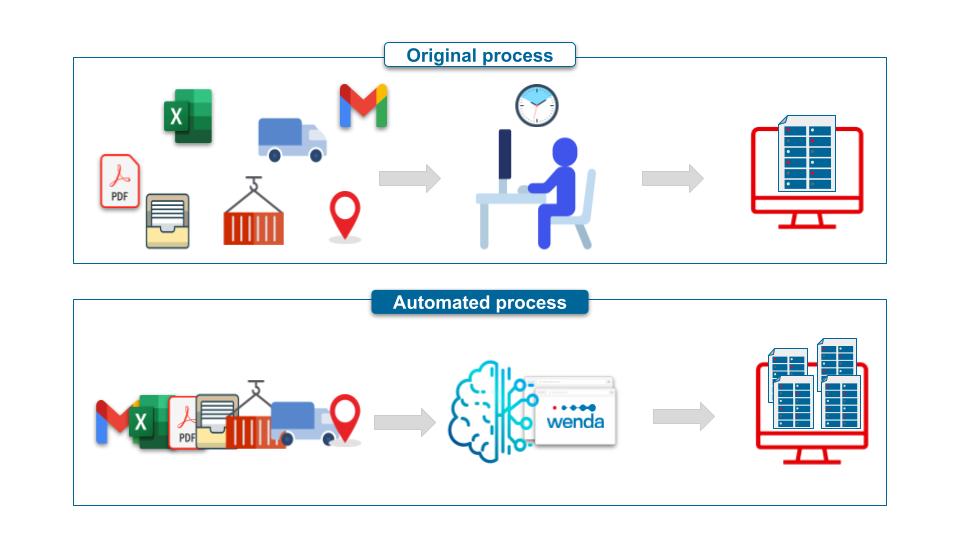

An evolved automation example for supply chain and logistics can be extracting data from sales quotes in PDF to automatically create Bill of lading draft and activate the monitoring of transiting containers. In this way, you will be activating the container tracking starting from a sales quote with minimum human intervention.

Today, various technologies and methods are used for process and data automation like Optical Character Recognition (OCR), with Artificial Intelligence (AI), Machine Learning (ML), Robotic Process Automation (RPA) and so on. It is a really rich world made of various strange abbreviations. Each of these technologies can be leveraged by different methods and applications depending on the scope.

Independently from the technology used, supply chain and logistics automation automates common manual tasks, operational activities and streamlines workflows and supply chain and logistics processes. It helps companies to lower the cost and the risk of errors and disruptions and drive more value from their workforce by simply freeing them from manual and repetitive activities.

Invisible robots: Software automation in supply chain and logistics

Automation in supply chain and logistics evolved drastically since the introduction of Henry Ford’s first assembly line in 1913. The development of new technologies gave a sprint to the businesses to transform and automate their operations. Today, supply chain and logistics automation refers not only to mechanical automation but also to automation of the operational activities and process automation.

It is still common that people think about “robotics automation” rather than “process automation” when we talk about automation in the supply chain and logistics area. This is mostly because the automation started on “mechanical activities”. For example, while today warehouse automation is widely known by the majority of the market, process automation is known by a smaller portion.

Robotics automation is a distinct branch of automation technologies. In the case of warehouse automation, it is about automating the movement of inventory into, within, and out of warehouses with the help of intelligent machines/robots.

“Some robots can be invisible and work very silently.”

On the other hand, process automation refers to any workflow that controls itself by use of computers and software¹. For example, automation of a specific operational activity like creation of transportation orders in TMS. This automation can be enabled by robotics (software), an intelligent machine that assists humans or by other technologies. This means when we talk about automation, it is not always necessary for automation to be enabled by robotics but if it is enabled by robotics, it is not always necessary to have hardware automation with physical robots. Some robots can be invisible and work very silently.

Since this article focuses on process automation and deep dives into related technologies, we can describe supply chain and logistics automation as follows:

“Supply chain and logistics automation means leveraging modern technology to automate common manual tasks, operational activities and streamline workflows and supply chain and logistics processes. It is simply an act of appointing technologies to execute some operational activities instead of a human being executing them manually.”

The definition often raises concerns about complete elimination of human involvement in the supply chain and logistics activities. Consequently, it raises questions about the dependability of these technologies. Supply chain consists of people, companies and processes. It is unlikely to think that it is possible to eliminate any of these components. On the contrary, technology gives us an opportunity to link these components together efficiently and simplify the interaction among them. It moves the burden of processes from humans to technology. More tasks are

performed by process automation means humans are free to engage in higher-value tasks.

“Supply chain is made by people, companies and processes. Technology gives us an opportunity to link these components together and simplify the information exchange among them.”

Supply chain and logistics automation is a technological response to the disruptions and unpredictability of today’s environment. It is a tool to help companies to adapt quickly to new changes. Traditional supply chain management is no longer able to give companies this flexibility. Therefore, most companies started to automate their supply chain and logistics processes with the help of technologies like Artificial Intelligence (AI), Machine Learning (ML), Optical Character Recognition (OCR), Robotics Process Automation (RPA) and more.

Digitizing and automating processes and data will lower the cost and the risk of errors and disruptions. According to a survey conducted by IBM, more than 50% of C-level executives use process automation and think that key operational processes can be augmented or automated using AI capabilities².

Gartner predicts that this will be a growing trend and over the next 10 years, businesses will progressively delegate decision-making authority to technology. Executives and supply chain managers must prepare their companies to respond to the opportunity³.

“Digitizing and automating processes and data will lower the cost and the risk of errors and disruptions.”

We will talk about the methods and applications that can help executives and supply chain managers to adopt process automation into their supply chain and logistics activities but, first, let’s elaborate the automation concept and the enabling technologies.

What is process automation?

A business process is defined by the behavior of people, systems, information, data and tasks or activities to complete in order to produce business outcomes in support of a strategy or of a specific objective. Process automation is when the whole process (or some part of the process) related to creation of the business outcome is an automated workflow that controls itself by use of computers and software.

In today’s businesses an overwhelming majority of the tasks and/or activities are data-related, and data-related tasks require people on a keyboard to enable processes, transactions or interactions. The automation of data-related tasks actually started in the 1960s with the introduction of Enterprise Resource Planning (ERP) systems. Today it has evolved and it is developed beyond simple “screen scraping” and “data sorting”⁴.

“Today automation has evolved and it is developed beyond simple screen scraping and data sorting.”

Data processing capabilities of screen scraping and data sorting is limited since these methods can ingest only structured, standardized data formats. Today, 80% of enterprise data consists of unstructured data. Moreover, the amount of semi-structured and unstructured data is growing very faster compared to the structured data. When the company operating processes do not have a fully digitized data recording or the contained data is unreliable, there is very little chance for screen scraping and data sorting to function correctly and efficiently.

Until very recently, the automation of tasks under these conditions required human intervention to be successfully completed. Now, the 1960s basic data movements are evolving into more advanced systems. It is not wrong to say that compared to basic data processing technologies, today, the capability of automating complex processes is increasing and poor user experience is decreasing.

Data-driven automation or Process-driven automation?

To fully understand the basics of process automation, we need to understand how the automation starts. So, the question is what is the source that guides the automation?

Process-driven automation is simply guided by processes. For this kind of automations, the focus is mainly on performing tasks through predetermined pathways and processes. The predetermined pathway remains quite stable and it is not possible to deviate from it since the process is the leading factor. When a task must be performed that does not fit within this predetermined pathway, and is therefore an exception to the rules, a human must intervene and take over⁵.

If you ever set up an “out of office” email then you have already performed process-driven automation. Automatically sent emails or automatically generated reports are very basic task automations. The advanced level can be automating complex processes, sometimes across multiple systems.

Compared to process-driven automation, data-driven automation is a further step in terms of complexity. In this case, automation is guided by data and context⁶. Data-driven automation is ready to deal with more complex processes. Here, the key to success is good quality data. The good quality data will help automation technology e.g. Artificial Intelligence (AI) to learn from the data and optimize process automation as a result. This accelerates the automation processes across multiple systems and data silos.

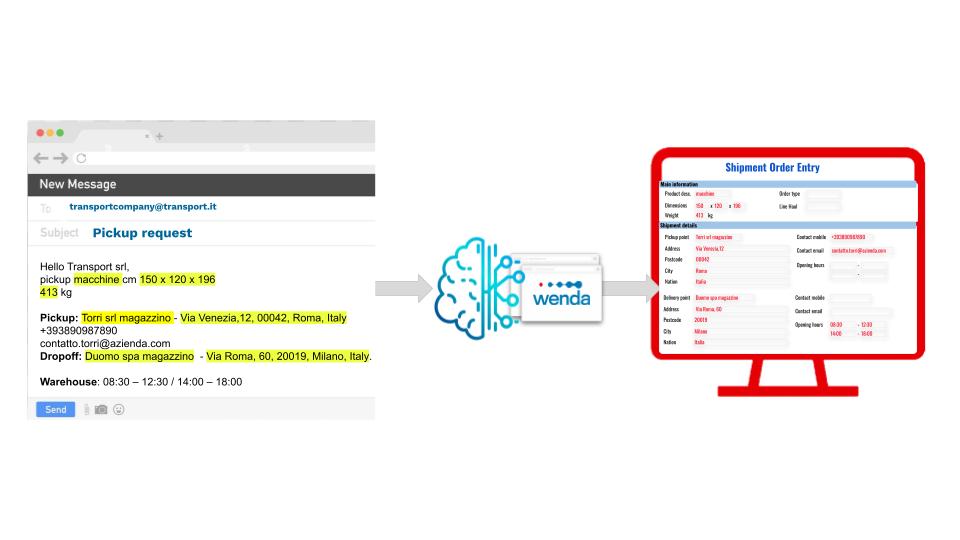

For example, automatically turning a customer request via email to pick up goods into a task into your TMS assigned to a person or a carrier is a very adequate example for a complex automation. It follows a clear logic of automating repetitive and routine processes: doing the exact same thing over and over.

Either way, process-driven or data-driven, automation and automated workflows streamline complex processes, freeing up the time of knowledge workers to be deployed on tasks that generate more value.

“utomated workflows streamline complex processes, freeing up the time of knowledge workers to be deployed on tasks that generate more value.”

The decision about the starting point – process or data – is more a technical choice for the development of an automation software or technology because it has a direct impact on the selection of enabling technologies (Artificial Intelligence (AI), Machine Learning (ML), Robotic Process Automation (RPA) etc.) and methods (Intelligent Document Processing (IDP), Business Process Automation (BPA) etc.). That is why it is mostly a concern of the technology provider rather than the business that automates its supply chain and logistics processes and activities, if the business did not opt for an in-house development.

What are the main technologies enabling process and data automation?

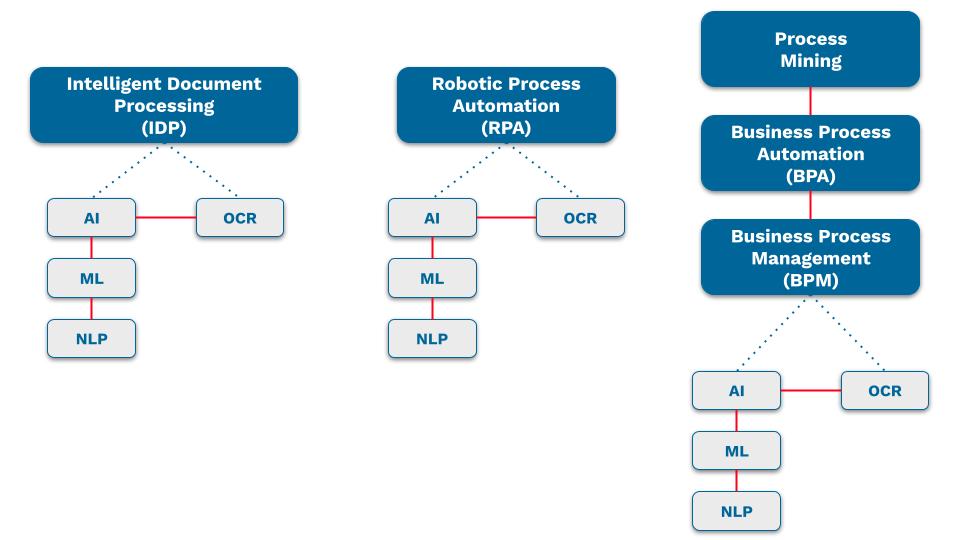

The world of technologies and methods used for process and data automation is a really rich world made of various strange abbreviations. The enabling technologies can be leveraged by different methods and applications depending on the scope. For example, when Optical Character Recognition (OCR) meets with Artificial Intelligence (AI), they create the basis for Intelligent Document Processing (IDP).

Each method and application has a particular focus. They can work both autonomously and in combination with each other.

Let’s start with explaining the core technologies. A simplified classification can be as the following:

Artificial Intelligence (AI)

– Machine learning (ML)

– Natural Language Processing (NLP)

Optical Character Recognition (OCR)

Technologies

1. Artificial Intelligence (AI)

In a most simplified way, Artificial Intelligence is the science of making machines do things that would require intelligence if done by man⁷. The concept of intelligence refers to some kind of ability to plan, reason and learn, sense and build some kind of perception of knowledge and communicate in natural language. Current AI technology can only do what it is designed to do. This means that for every problem, a specific algorithm needs to be designed to solve it.

1.1 Machine learning (ML)

Machine learning (ML) is a subset of AI techniques which use statistical methods to enable machines to improve with experience. If for example you want to write an algorithm to identify packing lists among other documents, you will have to train the algorithm by exposing it to many examples of documents that are manually tagged as being packing list or not-packing list. The algorithm learns to identify patterns, like occurrence of certain data or combinations of data, that determine the chance of a document being a packing list. Depending on the technique used, an algorithm can improve itself with time while ingesting more examples⁸.

1.2 Natural Language Processing (NLP)

Natural language processing (NLP) is a branch of artificial intelligence, concerned with the interactions between computers and human language. It is the ability of a computer program to understand human language as it is spoken and written, referred to as natural language⁹. NLP enables computers to understand natural language as humans do. NLP uses AI to take real-world input, process it, and make sense of it in a way a computer can understand. The machine learning algorithms produce an estimate about a pattern in the data based on some input data, which can be labeled or unlabeled. In this way, the algorithms make predictions or classifications. The algorithms constantly evaluate and optimize the classification or prediction process, updating weights autonomously until a threshold of accuracy has been met.

2. Optical Character Recognition (OCR)

OCR (Optical Character Recognition) is the use of technology to identify printed or handwritten text characters inside digital images of physical documents, such as a scanned paper document. The basic process of OCR involves examining the text of a document and translating the characters into code that can be used for data processing. This technology sometimes can be referred to as text recognition¹⁰. Usually, OCR technologies have two components: hardware for the digitalization of the document and software for converting documents into machine-readable texts. The software can leverage AI technologies.

OCR is a part of the Computer Vision world. The goal of computer vision is training computers to interpret and understand the visual world and derive meaningful information from digital images. Computer vision technologies work much the same as human vision. When trained, these systems can inspect or analyze thousands of images, noticing issues imperceptible to human eyes

“Each method and application has a particular focus. They can work both autonomously and in combination with each other.”

As mentioned, there are numerous methods and applications leveraging one or more of these technologies. These technologies do not work perfectly in isolation but they come usually as bundled solutions.

The best known ones can be listed as follows:

Intelligent Document Processing (IDP)

Robotic process automation (RPA)

Process Mining

– Business Process Automation (BPA)

– Business Process Management (BPM)

1. Intelligent Document Processing (IDP)

Intelligent Document Processing (IDP) refers to the extraction of information from paper-based and electronic documents and the utilization of this information to enable the end-to-end automation of document-centric processes. It leverages Artificial Intelligence (AI), Machine Learning (ML), Natural Language Processing (NLP) and advanced OCR engines.

IDP solutions capture, extract, categorize and analyze information from different types and formats and allow users to seamlessly integrate the output data into workflow automations. An IDP solution includes the following core capabilities¹¹:

Ability to process unstructured and/or semi-structured data

Data recognition & classification

Automated data extraction

AI & ML tools to categorization and analysis

OCR to capture data

Integrations with other data management softwares

2. Robotic process automation (RPA)

Robotic process automation (RPA) is a method that emulates the way humans interact with software to perform high-volume, repeatable tasks. It allows a user to create “software programs” or “bots” that can log into applications, enter data, calculate and complete tasks, and copy data between applications or workflow as required¹².

When combined with AI and ML, RPA can capture more context from the content it is working with by reading text or handwriting with optical character recognition (OCR), extracting entities like names or addresses using natural language processing (NLP), and capturing more context from images. Many RPA solutions are easily installed prebuilt software tools that run compatibility with the existing systems without connecting to databases or accessing Application Programming Interfaces (APIs).

IDP solutions and RPA softwares overlap since both methods involve automation of repetitive tasks. However, IDP solutions often complement RPA softwares because whereas an IDP system optimizes unstructured data to enhance workflows, RPA software designs and employs bots to handle simple tasks. Therefore, IDP can ensure that the high quality is integrated into automated workflows.

3. Process Mining

Process mining is a method designed to discover, monitor and improve real processes by extracting readily available knowledge from the event logs of the company IT systems like ERP, CRM etc¹³. It gives you the actual map of the actual process.

When the outcome of the discovery and analysis is the ideal process, indicating how to improve and optimize business processes it is called Business process management (BPM).

If we introduce the automation element the term will slightly change and become Business Processes Automation (BPA). BPA is defined as the automation of complex business processes and functions beyond conventional data manipulation and record-keeping activities, usually through the use of advanced technologies¹⁴. In contrast to other types of automation, BPA solutions tend to be complex, connected to multiple enterprise IT systems, and tailored specifically to the needs of an organization.

Both BPM and BPA attempt to improve tasks and processes that are repeated, ongoing, or predictable. While the BPM takes a wide view of the organization, BPA is a strategy to improve specific processes.

All of these technologies and methods listed above have a really wide range of applications. They can be provided by technology providers as a distinct solution or they silently power specific solutions. Today, many supply chain solutions are powered by AI technology: some enabling predictive analytics, some calculating Estimated Time of Arrival (ETA) and some others automating supply chain and logistics activities.

Simplified explanation: how does process and data automation work?

The technologies explained above and all the abbreviations can be really confusing. Especially, if one is not familiar with these technologies. If this is the case for you or you simply do not have time to explore everything and want to understand only the crucial parts, here is a really simplified explanation to how process and data automation work.

“3 steps to follow in order to start a process and data automation.”

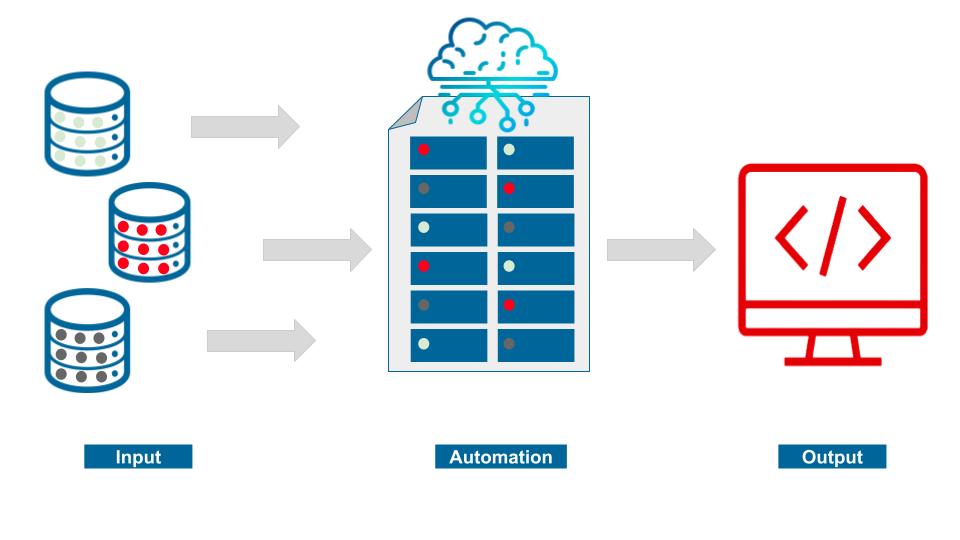

In principle, it follows 3 steps:

1. Extraction: Extracting the input data from one or many sources.

2. Transformation: Harmonizing and standardizing the data and then transforming it into the necessary structure.

3. Loading: Loading the data into the final system.

Our starting point is the data and our aim is to create intelligent and automated workflows. So, we focus on selecting data, choosing the automation we would like to realize and what to do with the output data.

In a real use case would look like this:

Process: “I would like to activate container tracking without manually inserting the container number into the visibility system. My suppliers send me a packing list via email, as a PDF attachment where I can find the container number to track my order.”

1. Choose one or more data inputs

“Packing list, PDF attachment to an email”

Focus on the input data.

Do not think about the data source. You can aggregate the data from any source: customer/vendor IT systems, Telematics or IoT devices, emails, excel files, DDTs, Packing Lists, orders, invoices, bill of ladings and more.

Do not think about document format and type. It can be in any format or type: email, text, excel, PDF, API, FTP, EDI etc.

2. Choose your automation case.

“Automatically activating container tracking”

What will be automated?

Let the intelligent algorithms do the rest.

3. Choose the output

“Receiving container number and supplier data into my Supply chain platform”

Correct the data if necessary. Remember: usually, the algorithms are in a continuous learning process. They can improve themselves with time while ingesting more examples.

Decide the destination of your output data. The output data will go on your ERP, TMS or on your Supply chain platform?

You are all set. In three simple steps you automated a time-consuming process and streamlined your operations. The enabling technologies and methods used in the backend can be complex but the automation itself is much more easier than it looks.

What are the use cases of process and data automation in supply chain and logistics?

The logistics and supply chain processes are labor intensive, error prone and fragmented in nature. A massive volume of communication among customers, suppliers, freight forwarders and carriers rely on paper-based manual methods, spreadsheets, emails or phone calls. According to the National Research Council of Turin, annually 1.2 million tons of paper are consumed by Italian companies. This number escalates drastically for the U.S. There are more than 30 billion paper documents that are annually copied and printed by organizations¹⁵.

A McKinsey analysis indicates that the bill of lading accounts for between 10-30% of total trade documentation costs. Adopting an electronic bill of lading could save $6.5 billion in direct costs and enable between $30 - $40 billion in new global trade volume while improving supply chain resilience¹⁶.

Also, a great part of the information necessary for executing critical supply chain and logistics operations are manually extracted from those data sources (email, spreadsheet) or from the existing systems (ERP, TMS, WMS). These kinds of operations are usually prone to errors during the data entry process causing inefficiency for companies.

“The logistics and supply chain processes are labor intensive, error prone and fragmented in nature.”

So, it is not surprising to see that there are many use cases for the digitization and automation of processes in supply chain and logistics. These use cases can vary from the area of logistics corridors and trade hubs, trade facilitation, consumer touch points and interaction, circular services, supplier relations, digital platforms and marketplaces, supply chain monitoring, risk management, trade and supply chain finance to decision making.

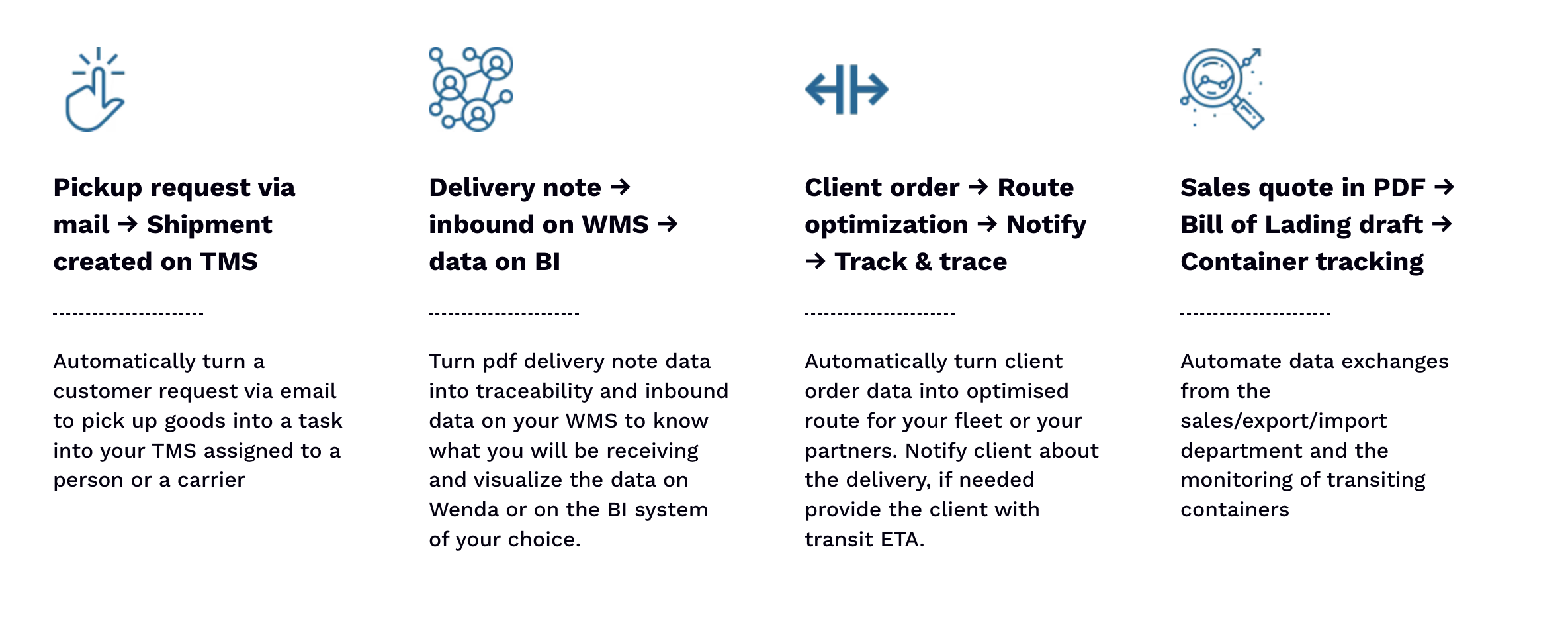

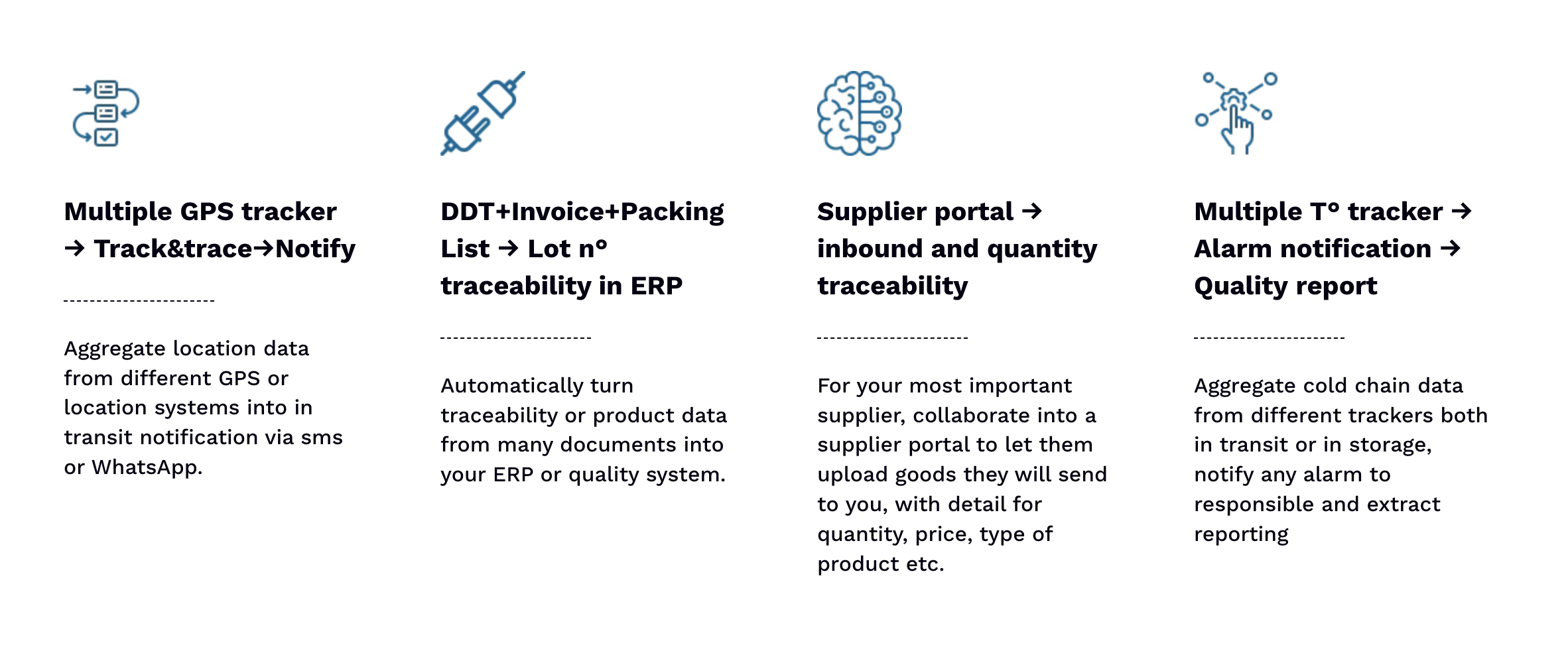

Here some specific examples of supply chain and logistics automations:

Pickup request via mail → Shipment created on TMS: In this case, you can automatically turn a customer request via email to pick up goods in a task into your TMS assigned to a person or a carrier.

Delivery note → inbound on WMS → data on BI: Starting from a pdf delivery note data, you can extract traceability and inbound data and receive on your WMS and visualize that data on a BI system or a Supply Chain Platform.

Client order → Route optimization → Notify → Track & trace: You can extract delivery details from client order data and have optimized routes created for your fleet or your partners. The automation would be pursued by notifying the client about the delivery, if needed providing the client with transit ETA.

Sales quote in PDF → Bill of Lading draft → Container tracking: Extracting data from sales quotes in PDF to automatically create Bill of lading draft and activate the monitoring of transiting containers. In this way, you will be automating data exchanges from the sales, import-export department and simplify the tracking process.

Multiple GPS tracker → Track Trace→Notify: Aggregating location data from different GPS or location systems to automatically receive in transit notification via sms or WhatsApp.

DDT+Invoice+Packing List → Lot n° traceability in ERP: Starting from a document like DDT, invoice or packing list to turn traceability or product data into your ERP or quality system.

Supplier portal → inbound and quantity traceability: Let your suppliers upload goods they will send to you, with detail for quantity, price, type of product etc. and start collaborating with them without phone calls and emails exchanges.

Multiple T° tracker → Alarm notification → Quality report: Aggregate cold chain data from different trackers both in transit or in storage and any alarm will be automatically notified to the responsible. You will extract reporting data according to the parameters you set.

You can easily notice that all the use cases explained above follow the fundamental principles of data and processes automation. You start with an input data, choose an automation case and deal with your output data.

“The more you eliminate the manual errors and break down the data silos, the more you will extract value from your supply chain and network data.”

It is important to connect the data and automatize the data flow because data creates value through connectivity. The more you eliminate the manual errors and break down the data silos, the more you will extract value from your supply chain and network data.

Why do companies automate their supply chain and logistics operations?

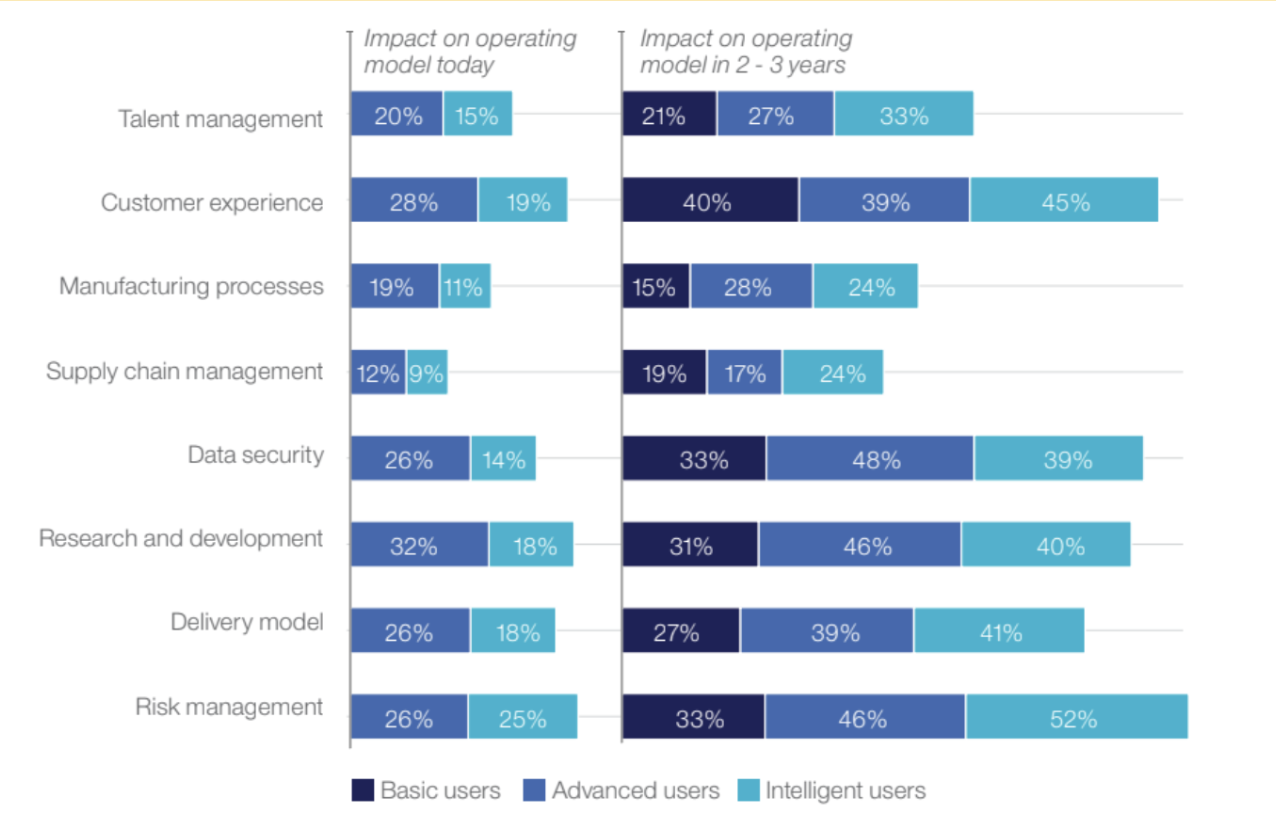

The supply and demand equation is under constant pressure and companies need to be able to make things happen at a far more accelerated rate. Streamlining operations and speeding up processes can create a real competitive advantage in this environment. Companies that fail to adopt AI and machine learning technologies to automate their processes and operations will be left behind. Early adopters have already started to implement these technologies and make automation an embedded part of their business processes. According to an IBM report, these companies already report achieving a significant impact from the use of their use across different business functions¹⁷.

“Companies that fail to adopt AI and ML technologies to automate their processes and operations will be left behind.”

Increase efficiency and productivity

The value of automation comes primarily from the efficiency it creates. One of the largest global consumer goods companies reported that using advanced automation to resolve workflow problems upward 30% more quickly and improve employee productivity by upward 50%¹⁸.

The figure below shows what is the impact of AI-driven automation capabilities on operating models today and what impacts users expect to see in 2-3 years. For the supply chain management, users report a 21% impact on their current operating models and aspects to see a 39% increase in the next few years¹⁹.

Source: IBM Institute for Business Value 2017 2Q C-suite research

A simple automation of processes can eliminate errors, reduce biases and perform operations and activities in a fraction of the time it takes humans.

Reduce costs and risks

As mentioned above, logistics and supply chain processes are labor intensive and error prone. Automating supply chain and logistics operations and activities will have an immediate impact on the errors and risks associated with these.

Did you ever realize that the information you inserted in a system has a minor error? So, you went and corrected it, sometimes just in time and other times after the error was made and the operations went further with the wrong information. Especially, when we need to take data and information from one source to another, the probability of making mistakes increases. Sometimes, even an unintentional mistype may lead to a more severe problem in the short or even long term.

Automation of manual and repetitive tasks has a direct impact on operational costs and risk reduction. By implementing the automation technologies, companies can save up to 75% of costs on repetitive tasks compared to human performance, with 25% to 50% being the generally reported outcome²⁰.

Gartner indicates that by 2022, 65% of businesses that have implemented Robotic Process Automation (RPA) will also introduce AI, including Machine Learning (ML) and Natural Language Processing (NPL) algorithms. The implementation of these technologies will enable them to reduce operational costs by 30% by 2024²¹.

For example, one European electricity supplier reported an estimated savings of EUR 6 million after only the first 8 of 50 planned task automations went operational and anticipated double-digit percentage cost savings over the course of the implementation²².

Automating mundane and repetitive tasks and operations brings higher precision and resilience to the companies by reducing the errors and improving the response time to resolve the errors.

Balanced workload and higher value

Automation is an opportunity to create new value from the three elements of the supply chain: people, companies and processes. The goal of implementation of these technologies is not replacing people but transforming the work that humans do and creating new ways of working²³.

Process and data automation can free up the time of qualified workers from routine work so they can be deployed on tasks that generate more value. The intelligent algorithms can run various repetitive operational processes more quickly than humans. In this way, the human workforce will recapture time to do what it’s best suited to do: think strategically, act creatively and interact humanely.

For example, one of the world’s largest pharmaceutical distribution providers implemented automation to solve enterprise application problems before they become incidents. The company processed millions of orders per day at a pace well beyond human capacity. In order to execute the operations the company needed to complete hundreds of repetitive, manual tasks. These tasks included the reconciliation of a large legacy ERP system to ensure that deliveries shipped were also invoiced. Recurring issues within the existing system were impacting the company’s end customers: While support staff worked to fix problems in the ERP system, trucks were kept waiting at warehouses for the information they needed to make deliveries.

The company automated monitoring activities in the ERP and dramatically reduced the need for manual intervention. Automation has enabled the company to redirect around 1100 man-hours each month - or over 13.000 hours per year – toward new project initiatives. This allowed the team to build and develop valuable project design skills²⁴.

According to Mckinsey Global Institute automation is rapidly transforming the world economy, in fact at least 30% of activities in about 60% of occupations in any industry can be automated. Today more than 70% of companies have different automation initiatives started but they are often disparate and siloed and not coordinated with business objectives across functions. By 2025 this will start to change and supply chain managers and professionals will roll out more coordinated initiatives²⁵. It would be a self harming decision for any business to try to resist this change instead of being a part.

Conclusions

Automation does not only indicate the robotics automations. It is important for companies to see the automation beyond a physical activity and focus on process and data automation. Especially, in today’s economy, supply chain and logistics automation is a solid technological response to the disruptions and unpredictability. Traditional supply chain management is no longer able to give companies the flexibility they need to adapt quickly to new changes.

The early adopters have already started their automation journey a while ago with the help of technologies like Artificial Intelligence (AI), Machine Learning (ML), Optical Character Recognition (OCR), Robotics Process Automation (RPA), Intelligent Document Automation (IDP) and more.

Automation of supply chain and logistics operations and tasks will eliminate time-consuming, manual and repetitive activities, free up time for workers and streamline operations. This will increase efficiency and productivity, reduce operating costs and risk, drive higher value from the employees and gain an important competitive advantage.

Notes

1. Disrupting Logistics (Future of Business and Finance)

2. IBM Institute for Business Value (2018): The Evolution of Process Automation

3. Gartner - From Automation to Autonomy: The Supply Chain 2035 Roadmap

4. IBM Institute for Business Value (2018): The Evolution of Process Automation

5. IBM Institute for Business Value (2018): The Evolution of Process Automation

6. Ibidem

7. Raphael, B. The thinking computer. San Francisco, CA: W.H. Freeman

8. Deloitte: Part 1: Artificial Intelligence Defined

9. TechTarget - A guide to artificial intelligence in the enterprise

10. TechTarget - OCR

11. TrustRadius- Intelligent Processing Systems

13. Gartner Market Guide for Process Mining 2021

15. Omdia, Market Landscape: Intelligent Document Processing

16. The multi-billion-dollar paper jam

17. IBM Institute for Business Value (2018): The Evolution of Process Automation

18. Ibidem

19. IBM Institute for Business Value 2017 2Q C-suite research

20. Ibidem

21. Gartner Press release, June 2021

22. IBM Institute for Business Value 2017 2Q C-suite research

23. World Development Report 2019 – The Changing Nature of Work

24. IBM Institute for Business Value (2018): The Evolution of Process Automation

25. Gartner - From Automation to Autonomy: The Supply Chain 2035 Roadmap

Chips war: tensions in semiconductors supply chains

Chips war: tensions in semiconductors supply chains How to increase back office efficiency in transportation companies

How to increase back office efficiency in transportation companies Secret ingredients for automation: AI and Machine Learning

Secret ingredients for automation: AI and Machine Learning Automated solutions to save back-office time

Automated solutions to save back-office time